Our Green Shape environmental standard for environmentally friendly products is a success story

We think entrepreneurship has a lot to do with responsibility. We understand this to mean that in all our entrepreneurial activities we think not only about the desired result, i.e. the production and marketing of outdoor products, but also about the impact this has on people and the environment. That's why we launched Green Shape in 2010 as our own label and standard for environmentally friendly products.

A lot has happened since 2010 - the percentage of Green Shape products in our collection has increased steeply year after year, and the criteria for Green Shape, which were strict from the beginning, are continuously being developed and tightened. This year we are aiming for external accreditation for Green Shape as an environmental standard. After more than 10 years now, we proudly look back on our Green Shape success story.

"We have a vision of a thoroughly sustainable company and want to objectively ensure that our products are manufactured in an environmentally friendly and fair manner."

Antje von Dewitz

2010 is the year Green Shape was born

The textile industry is a burden on the environment. Many materials contain carcinogenic, hormonally active or otherwise toxic chemicals: starting with harmful fluorocarbons (PFCs) to softeners and solvents. In addition, water consumption and pollution as well as unfair working conditions in the textile industry are problematic.

We want to be part of the solution for greener textile manufacturing.

To this day, our CEO Antje von Dewitz is of the opinion: "We as manufacturers of textiles are part of the problem, but we want to be part of the solution. We are aware that our business activities involve a burden on our environment and that the resources of our planet are finite. We accept this responsibility and are constantly working to keep our environmental footprint as small as possible. "A central building block towards fulfilling this goal was the introduction of VAUDE's own environmental label "Green Shape" in 2010, which has since stood for functional, environmentally friendly products made from sustainable materials that are manufactured in compliance with fair working conditions.

Why was Green Shape invented in the first place?

"It was about completely and consistently redirecting our product development toward sustainability," Antje von Dewitz recalls. in 2010, however, there was still no suitable, overarching evaluation system for our products worldwide. At VAUDE, we had already been a bluesign® system partner since 2001, one of the world's strictest standards for environmental protection in textile production. VAUDE was already processing many bluesign® system certified materials at that time, but for the production of outdoor products we used a variety of different materials such as synthetic fibers, metals or natural materials. And each individual material required its own standard, which was not always covered by bluesign®.

Because there was no comprehensive sustainability label for textiles, we tackled this ourselves

So we decided to create our own meta-label that would be based on the most stringent textile and environmental standards, while also looking at the entire product life cycle. The starting point was the desire expressed to us by retailers to develop a label that would be relevant to consumers and that would identify environmentally friendly products. So we set to work designing Green Shape. Hilke Patzwall, our CSR manager, played a key role in developing Green Shape and was involved from the very beginning.

«In 2009, we established the first criteria that our materials had to meet in order to receive the Green Shape label. We aimed to set the world's strictest textile standard for outdoor products.»

Hilke Patzwall

A challenging task. A comprehensive catalog of criteria and a strict evaluation system were developed. But for this, many questions had to be clarified. For which materials and substances were there meaningful certificates or standards apart from bluesign®? Were problematic chemicals substitutable? And how was it going to be possible to involve the producers? In the difficult question of evaluating different natural materials, we had the support of our long-standing cooperation partner World Wide Fund for Nature (WWF), but also many outdoor and sports retailers.

"We were a pioneer in the industry. Developing our own environmental standard was pioneering work. It cost us a lot of nerves and a lot of time, but it was worth it," says Hilke Patzwall.

To get a Green Shape label, each product had to be made of certified and/or particularly environmentally friendly material, and at the same time the manufacturer of the material had to be environmentally certified. Then, internally, we set clear targets year by year for how large the proportion of Green Shape products in the collection should be.

Clear strategy with regard to harmful substances and chemicals

Under the leadership of Bettina Roth, we set up our own chemical management as part of quality management. "The first thing was to systematically test which materials actually had harmful substances in them," Bettina Roth recalls. Up to that point, this had not been common practice in the industry. It turned out that there were major differences in quality and levels of knowledge among our suppliers. It also quickly became clear to us:

«Testing the finished end product for harmful substances was the wrong way to go. We had to start with the materials.»

Bettina Roth

The question now was how to keep harmful chemicals out of the production process. Bettina and her team began to define substances and pollutants that are either completely banned or limited by threshold values. We based our work on the current state of knowledge and worked closely with key players such as bluesign®. Over the years, a list known in technical jargon as the Manufacturing Restricted Substance List (M/RSL) evolved and was updated again and again. The ambitious goal: to completely ban harmful substances from production. All VAUDE producers committed to comply with these specifications.

Our comprehensive chemicals management goes far beyond the legal requirements.

With this strategy, we at VAUDE have gone and continue to go far beyond the legal requirements. "Through the consistent use of MRSL-compliant chemicals and a certified environmental and occupational health and safety management system in the production facilities, we have succeeded in working with certified materials that meet the highest standards in the area of sustainability. This includes ensuring that these materials are produced with no or the lowest possible risk to the environment and local employees," explains Bettina Roth.

From obstacles, mischief and Conflicts to initial successes in the outdoor retail trade

The path to environmentally friendly materials was not easy: Our product managers were afraid of losing important suppliers with whom they had worked for years, and it was extremely difficult to even find materials that met the Green Shape criteria. In addition, they were much more expensive than conventional materials. Some manufacturers did not even participate due to the additional costs of auditing. In addition, our sales colleagues received feedback from retailers that there was hardly any demand for environmentally friendly products among consumers. The banks also dismissed our management's ambitious plans as "rubbish" that would not make money.

"There were fierce conflicts at many levels in the early years," Antje von Dewitz recalls.

But with a clear vision in mind, many discussions, training sessions and courses, things progressed step by step. An interdisciplinary sustainability team led by Jan Lorch (Sales & CSR Management) brought the sustainability idea to the various departments and kept looking for viable solutions. Successes were also achieved because all departments worked together and hand in hand to implement the initially challenging Green Shape criteria.

Gradually, however, more and more customers* began to take an interest in an ecological VAUDE collection. in 2011, in cooperation with Sport Scheck, we were allowed to fill our own Green Shape retail spaces for the first time. Green Shape developed into a success story - interest in environmentally friendly outdoor products was awakened.

"That felt great and was a hugely important confirmation on our path," Antje von Dewitz recalls.

There was a lot of turbulence on the way to PFC-free outdoor gear.

There have been some daunting challenges to overcome in Green Shape's history. In textile production, poly- and perfluorinated chemicals (PFCs), also known as fluorocarbons, are particularly critical. They are not biodegradable, enter the environment via wastewater and also accumulate in the human organism via the food chain. They are also suspected of being carcinogenic.

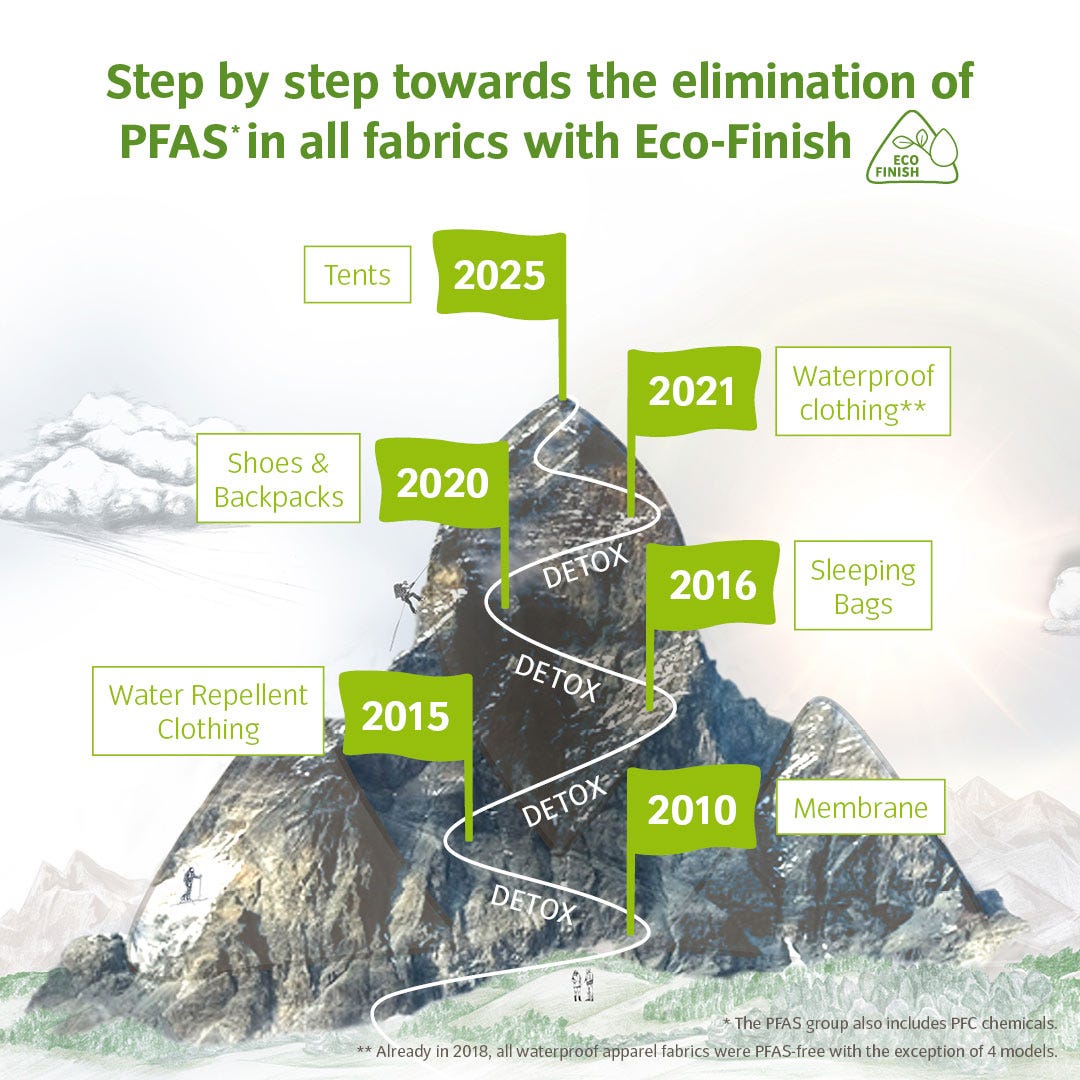

We were aware of the problem and set out in 2010 to ban PFCs from our collection. Initially, we replaced all waterproof membranes containing PFCs, which were used in our rainwear, for example, with PFC-free alternatives. The problem, however, was the impregnation of the outer fabrics, which provides the so-called beading effect. At that time, there was no viable alternative on the market, and we started extensive trials with our partners to ban PFCs from the collection. Initially, however, without success.

Greenpeace's Detox campaign finally brought the necessary movement into the industry

It wasn't until Greenpeace's "Detox Campaign", which called on the textile industry to renounce all chemicals that are hazardous to health and the environment, that the decisive pressure was put on the entire industry and thus provided the impetus for faster development. In 2016, VAUDE became the first major outdoor brand to sign the Greenpeace Detox Commitment. In it, we voluntarily committed to eliminating harmful substances from the supply chain and to report extensively on this.

After a period of hard work with real test marathons, the first successes began to emerge. In close cooperation with our chemical suppliers, we developed various PFC-free impregnations, which we have since labeled "Eco Finish. in 2015, Eco Finish became another criterion for the award of the strict Green Shape Standard.

Our Green Shape products will receive the government's Green Button seal for sustainable textiles in 2019.

As a medium-sized family business, it was not always easy to change the framework conditions on our own, especially in the supply chain and in textile manufacturing. For a long time, our management has been advocating for joint action by the entire industry and political support. And so it was only logical that VAUDE became a founding member of the German government's Alliance for Sustainable Textiles (in german) in 2014. "That was a great opportunity to be able to effect change together," Antje von Dewitz recalls. Because for the first time, the German government, the textile and clothing industry, retailers, trade unions and civil society voluntarily pooled their expertise and forces with the aim of putting internationally recognized environmental and social standards into practice better than before throughout the entire textile production value chain.

We made the criteria stricter year after year and set ourselves ambitious targets

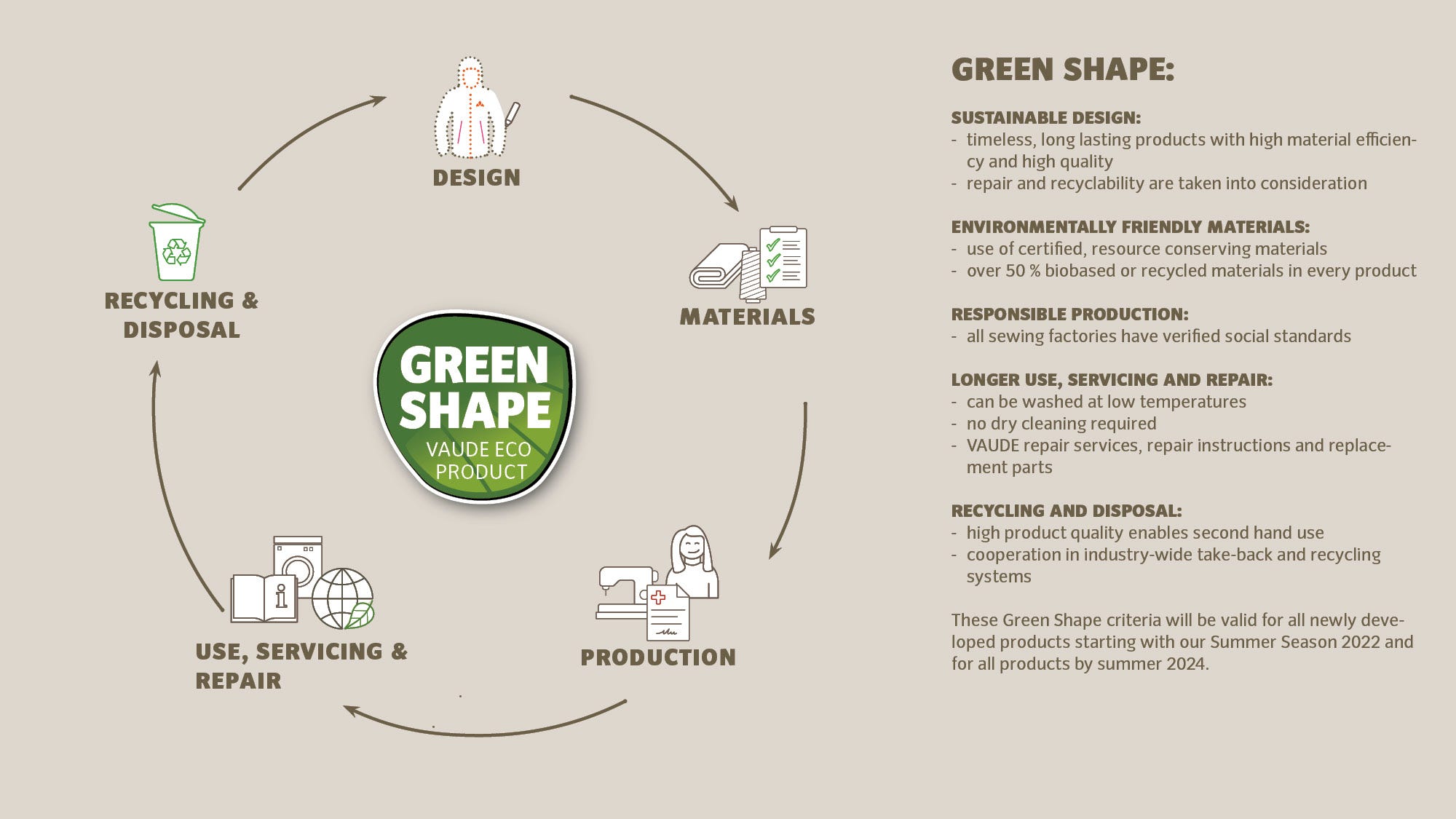

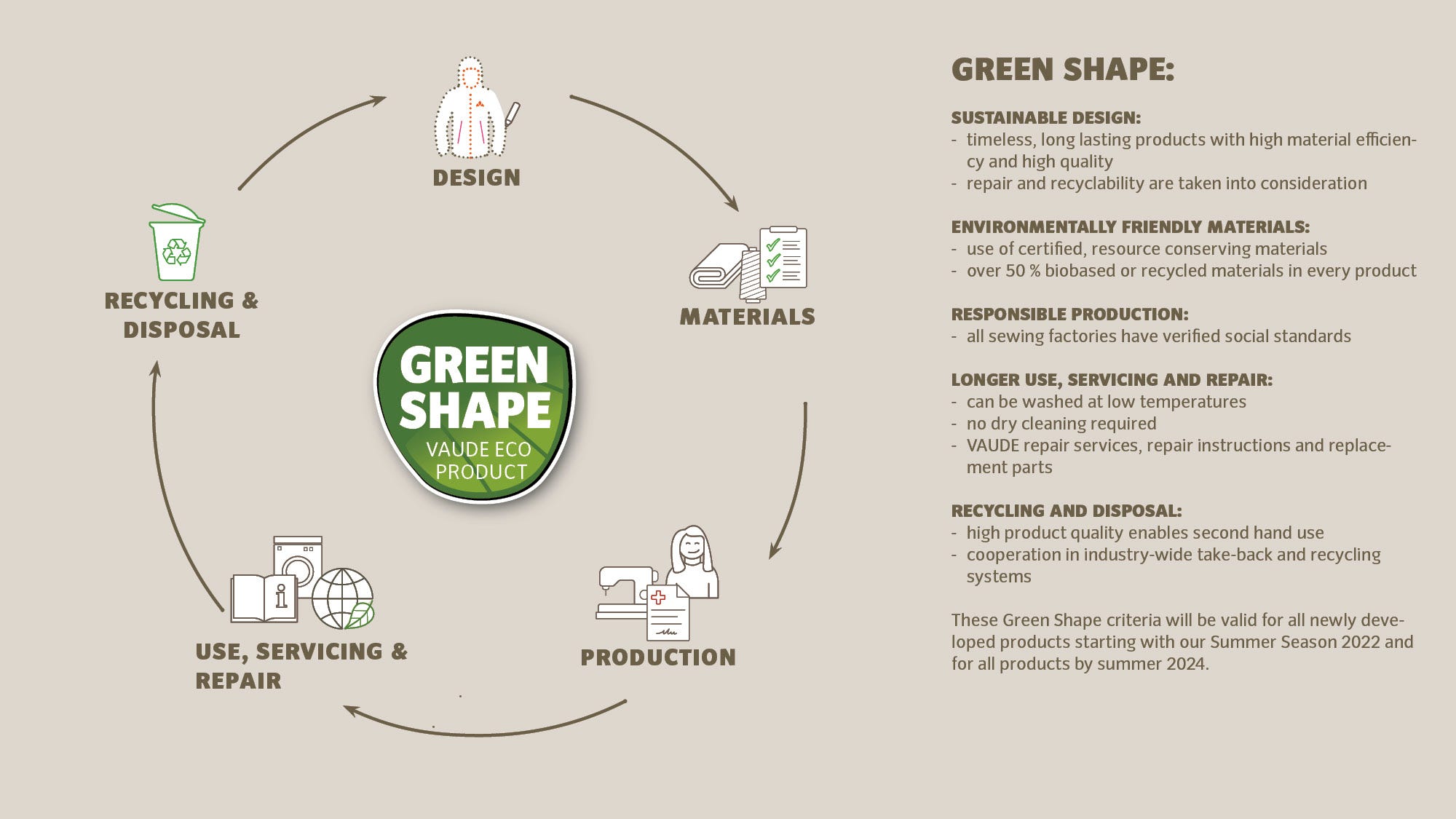

Meanwhile, work on the Green Shape Standard continued. in 2015, the criteria, which initially applied only to materials, were expanded to cover the entire production cycle: Starting with the design, the materials used and their manufacturing processes, the production sites and the use and care of the product, and ending with the most environmentally friendly disposal possible. The proportion of Green Shape products rose steadily year on year. Whereas in 2010 they could be counted on one hand, by 2020 almost 100 percent of the clothing and almost 90 percent of the rest of the collection had already been awarded the Green Shape label.

Products with the Green Button (Grüner Knopf)

Our Green Shape products carry the german government seal for sustainable textiles.

in 2019, the next success followed for the Green Shape concept: under Development Minister Gerd Müller, the German government established the first government seal Green Button for socially and ecologically sustainably produced textiles. Consumers were thus to be given better guidance when making purchases. This is because all products with the Green Button may only be produced in compliance with government-defined criteria according to high environmental and social standards.

VAUDE was significantly involved in the creation and conception of the Green Button. Particularly gratifying: the Gesellschaft für internationale Zusammenarbeit (GIZ), an agency of the German Federal Ministry for Economic Cooperation and Development (BMZ) recognized Green Shape as the standard for the Green Button.

"The fact that Green Shape was recognized for the Green Button was a huge success and valuable confirmation that we had taken the right path with our strict Green Shape criteria," says CSR Manager Hilke Patzwall today.

Circular thinking is at the heart of Green Shape

But we are not resting on our laurels: For the 2022 summer collection, Green Shape got a new update. Every new Green Shape product must now be made predominantly from recycled or bio-based materials. This saves climate-damaging emissions and supports the development of a circular economy. Other criteria that must be met, such as repairability, material efficiency or recyclability, also pay towards this goal. And again, we are a pioneer in this area: hardly any other brand even includes these strict criteria in product development to date.

What do the Green Shape criteria mean for the reparability of our products?

We have developed our own repair index so that reparability is consistently considered throughout the entire product development process. That's why, for example, our bicycle bags have buckles that can be replaced easily and in just a few steps. We have also been offering our own repair service for many years and cooperate with many repair cafés. In addition, we offer "do-it-yourself" repair instructions including orderable spare parts both on our own website and on the online platform iFixit (in german).

Waste avoidance, repairability, material efficiency and the use of recycled materials are criteria for Green Shape

In addition, our product designers are working intensively on the question of how to generate as little waste as possible during production. Optimal material efficiency is the magic word, which leads to hardly any waste through the perfect coordination of cut and design. In this way, valuable resources are conserved.

A new addition is also the topic of recycling and disposal. VAUDE products are designed and created to last as long as possible and to be repairable. But even the most functional, durable and repairable product will eventually reach the end of its product life cycle. Unfortunately, textile recycling is still in its infancy - so far, only about 1% of all textiles are recycled at all. Nevertheless, we at VAUDE are already taking action with the Green Shape criteria. Hilke Patzwall explains, "We already anchor criteria in product development for which materials and processing technologies are selected, because ideal for material recycling are products made of materials that are as pure as possible and can be easily separated from one another."

Need a spare part?

We offer spare parts for many products and show you how to make small repairs yourself.

All materials are evaluated according to their recyclability as well as the current state of the actual recycling infrastructure. for materials that are not or only very difficult to recycle (e.g. spandex or polyurethane), our product managers* check if they are really necessary for the function of the product, or if at least their share in the product can be reduced. All of this is anchored in the VAUDE Material Policy.

Climate protection thanks to a wide range of recycled materials

Not only to meet the Green Shape goals, but also to meet our own ambitious climate targets, more than 90% of all VAUDE products should have a recycled or bio-based material content of more than 50% by 2024.

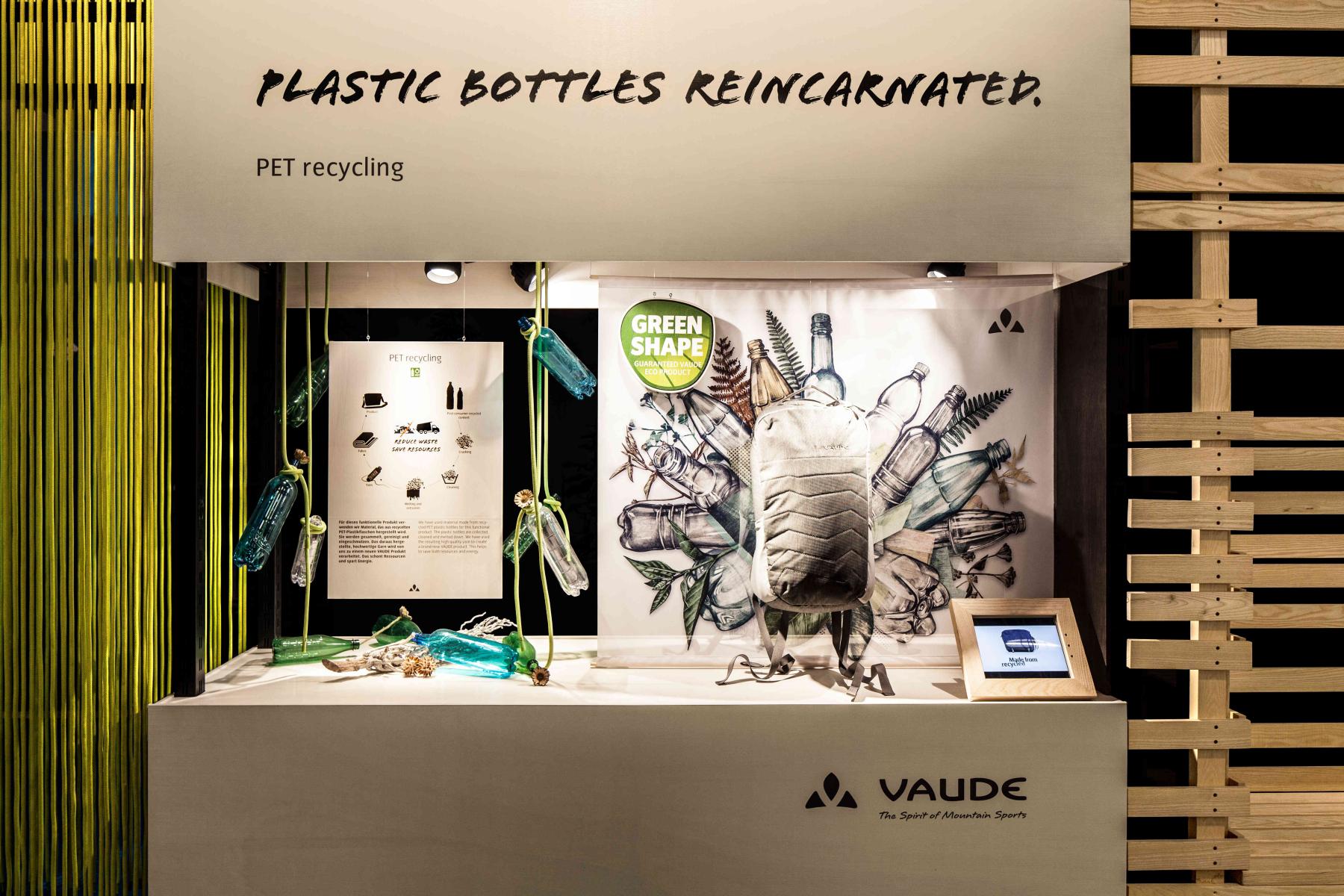

Recycled PET bottles and used tires are a valuable raw material for our products.

There is now a wide range of recycled and bio-based materials that are used: Whether recycled PET bottles, recycled coffee grounds, recycled fishing nets, recycled down or bio-based fabrics made from castor oil or corn, for example. Brand new to this long list is the recycling of used tires for the production of polyamide.

Using a mass balance process, plastics that are difficult to recycle, such as used tires, can be used to make polyamide. The resulting sustainable polyamide is just as functional as conventional, but saves about 60% in CO2 emissions during production. This material is now used in many items of clothing, such as trekking pants, and from the 2023 summer collection also in backpacks or bicycle bags.

The Green Shape Success story continues...

What is certain is that the Green Shape success story is far from over. The goal continues to be that the products become even more environmentally friendly, that the ecological footprint becomes continuously smaller and that nature and the climate are less and less burdened by the production of outdoor gear.

"In addition, we are striving for external accreditation so that Green Shape becomes an environmental standard that is equally valuable and valid for all stakeholders," explains CSR Manager Hilke Patzwall. For this reason, a Green Shape advisory board of external experts was recently established to incorporate the independent expertise of scientists, consumer representatives, retailers, the media and environmental organizations in the further development and accreditation process.

The Green Shape environmental standard is one of our most important building blocks when it comes to doing business in a holistic and forward-looking way, VAUDE CEO Antje von Dewitz is convinced of this:

"We must act with all our might to preserve the basis of life for future generations. This is exactly what has driven me and all of us at VAUDE for many years: Doing business in a sustainable and forward-looking way means actively standing up for climate protection - for the future of our children and for the future of our planet."

Want to learn even more about Green Shape?

You can learn more about our environmentally friendly Green Shape products here and if you want to dive even deeper into how our environmental standard works in detail and which criteria we all take into account, click into our sustainability report.